Steel coil wrapping machine FPS-600

The machine offers exceptional performance and safety features, utilizing international standard components for easy replacement and local accessibility. Its design focuses on efficiency, reliability, and user-friendly operation, making it ideal for handling and wrapping coils with precision and safety.

Key Features:

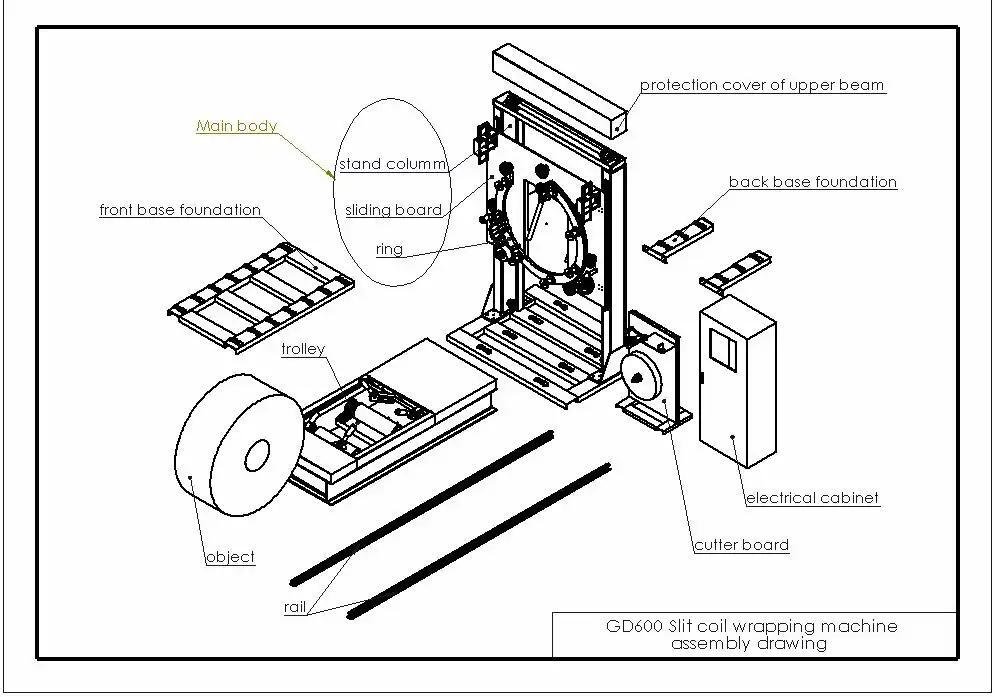

Advanced Control System: Equipped with PLC, HMI, and inverters for seamless operation.

Efficient Coil Handling: Includes a loading trolley with a truck for safe and reliable movement.

Adjustable Ring Board: Motor-driven center adjustment for different coil sizes.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The FPS-600 steel coil wrapping machine offers reliable, high-speed wrapping for steel coils, providing a tight and consistent seal to protect against moisture and handling damage. Its user-friendly interface and adjustable settings make it adaptable for various coil sizes, improving operational efficiency and package durability.

Basic features

1) Excellent collections. international main components for easy get on local market.

2) PLC with HMI and inverters

3) Loading Trolley with truck that is the way for the coil hadnling safe and movement reliable.

4) The ring board center adjustmable for packing the different coil OD by motor driving.

5) Two layer packing material wrapping at one time.

6) Wrapping film tension is adjusted by special tension control system to achieve the good wrapping effect for all the size of coils.

7) Protective guard of ring part for safe operation.

8) The overlapping can be adjusted by converter according to needs.

9) Ring soft turning and high speed turning in different wrapping procession.

10) One bottom Packing position reset .

11) Motor Overloading protection.

12) Safety limitations in ring ratating and coil rolling .

13) Guardrail for the running part ensures safe operation.

14) Ring speed and roller speed are adjustable by converter.

15) Independent electrical control cabinet for easy operation and maintenance.

16) Friction of wheel postiion adjustable for ring smooth rotation and long life of the wheel.

17) Soft PU wheels for ring surface protection.

18) Packaging time is available for setting on control panel for automatic stop.

19) Machine reinforce machine structure with long using life.

20) Indicator automatic alarm.

Option parts:

a. Special film tension control system

Providing consistent packing tension for small and big wire coil for tighten packaging.

b. Automatic material cutter

Automatic material feeding and cutting to avoid manually job in material tie on coil and cutting.

It is a special cutter which working for cutting the stretch film&paper together.

c. Interlock

Fortress interlock for rotate part

d. HMI

It is for panel control the machine which is necessary part for automatic cutting.

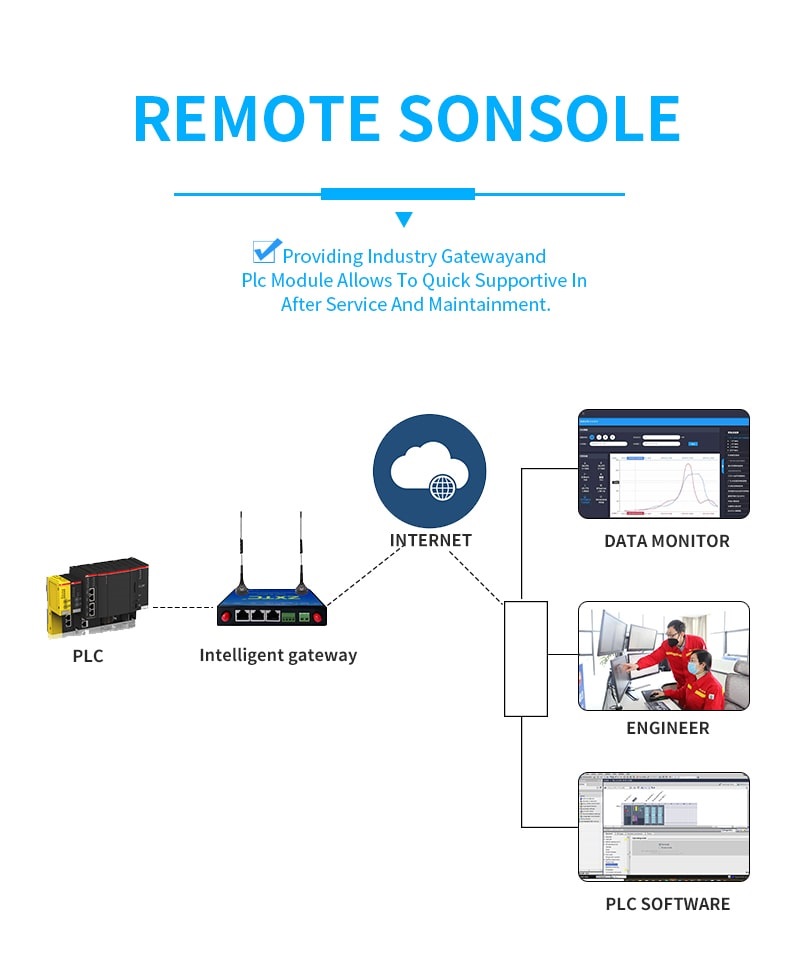

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635