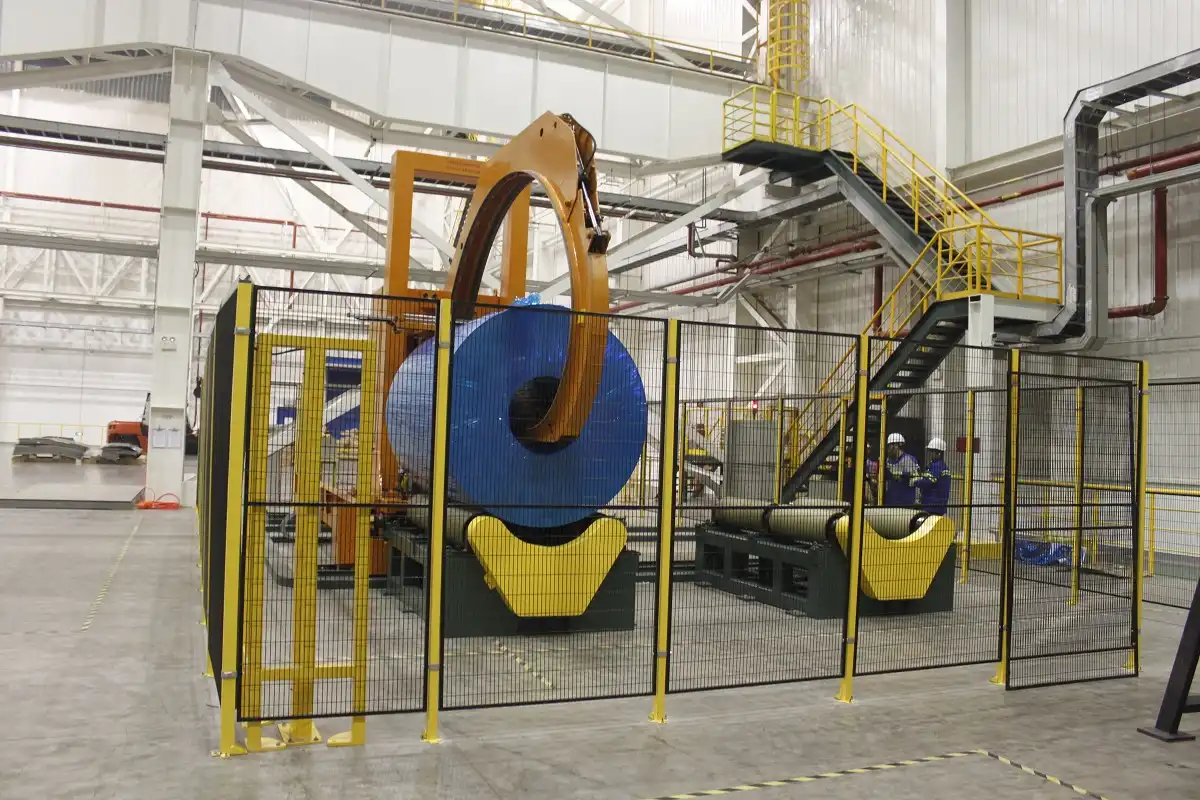

Master coil stretch wrapper

The Master Coil Stretch Wrapping Machinery by FHOPE offers advanced automatic packaging solutions using VCI film for steel and aluminum coils. Its innovative eye-through wrapping technology ensures safe, efficient, and customized operations for diverse coil types, backed by compliance with stringent safety standards.

Key Features:

Advanced Power Connection: Ensures reliable and efficient energy supply for uninterrupted operations.

Shuttle Drive System: Enhances precision and stability during the wrapping process.

Customizable Design: Tailored for different coil sizes and materials, including steel, aluminum, and copper.

Safety Compliance: Equipped with interlocking systems, safety guards, and CE-certified components for secure operation.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The Master Coil Stretch Wrapper FPS-2000 is an advanced wrapping machine engineered for industrial coil packaging. Capable of handling heavy loads up to 10,000 kg, it supports various packing materials and customizable overlap settings, ensuring reliable protection. This versatile solution optimizes efficiency and safeguards coils during transport and storage.

Master coil stretch wrapping machinery

The automatic coil stretch wrapping system for master coil wrappers utilizes VCI film to deliver advanced packaging solutions. This eye-through wrapping technology marks a significant leap forward, featuring innovative power connection and shuttle drive systems tailored for packaging steel and aluminum coils. Developed by FHOPE, the system integrates microchip technology and cutting-edge engineering, making it a reliable choice for the steel industry.

Customized Solutions for Various Coil Products and Materials

Our team specializes in providing customized solutions for diverse coil products and packing materials, including:

Aluminum Coil

Steel Master Coil

Copper Coil

Stainless Steel Coil

Wire Rod Coil

Safety and Compliance Features

The equipment is designed to comply fully with safety regulations, ensuring seamless and secure operation. Key safety features include:

Compliance with local safety standards guaranteed by the Seller.

Interlocking safety systems installed on the control board.

Safety-enabled drives for all main motors.

Complete safety guards for operational areas, accompanied by CE declaration forms.

Additionally, the cabling adheres to effective regulations, ensuring durability and safety:

Concrete Foundation Cabling: Cables are laid in conduits within the concrete foundation for stability.

Exposed Cabling in Hazardous Areas: Cables in hazardous zones are protected with hoses placed on top of the concrete.

Connection of Components: Termination switches and magnetic valves are connected directly to bus modules within terminal boxes or substations.

This design ensures the highest levels of safety and operational efficiency, making it a trustworthy solution for modern coil packaging needs.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635