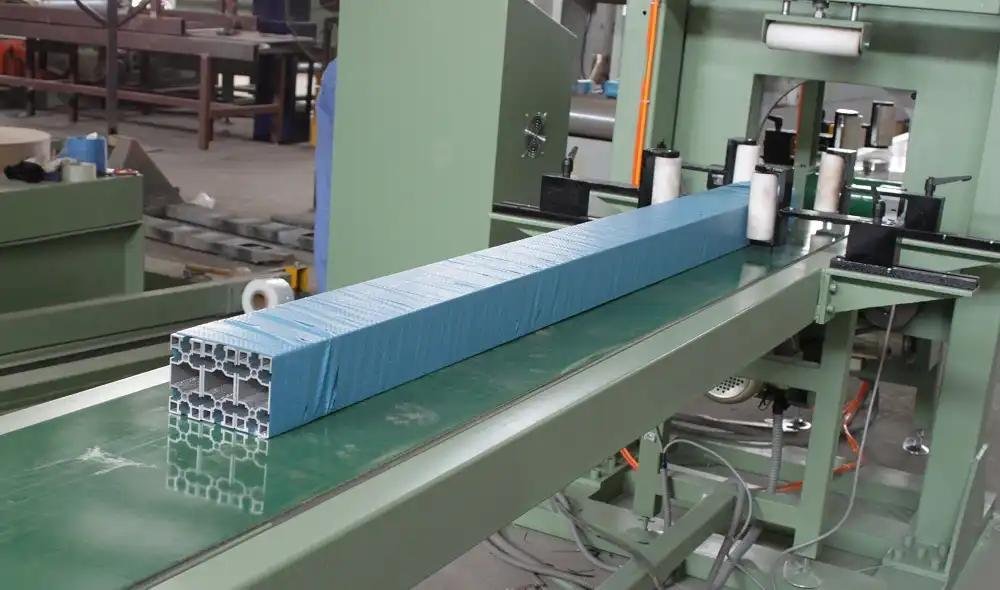

Aluminum Horizontal Orbital Wrapping Machine

The Aluminum Profile Wrapping Machine is a cutting-edge solution designed for efficient and secure packaging of aluminum profiles, rods, and bars. With advanced automation, customizable features, and seamless integration options, it ensures high-quality packaging while reducing labor and material costs.

Key Features:

PLC and HMI Control: Offers precise operation with auto and manual modes.

High-Speed Ring Rotation: Ensures rapid and even wrapping at up to 100 RPM.

Customizable Wrapping Settings: Adjustable speeds, overlap rates, and tension for tailored packaging.

Automatic Film Handling: Cuts, feeds, and detects errors for uninterrupted operation.

Robust Conveyor System: Supports continuous packaging for various sizes.

Enhanced Package Protection: Prevents shifting or damage during transportation.

Special Features

Related video

The Aluminum Horizontal Orbital Wrapping Machine is tailored for efficient and secure packaging of aluminum profiles, rods, and sheets. Designed for precision and durability, it ensures consistent wrapping performance with adjustable tension and speed settings. Ideal for industrial use, it enhances product protection during storage and transportation.

Overview

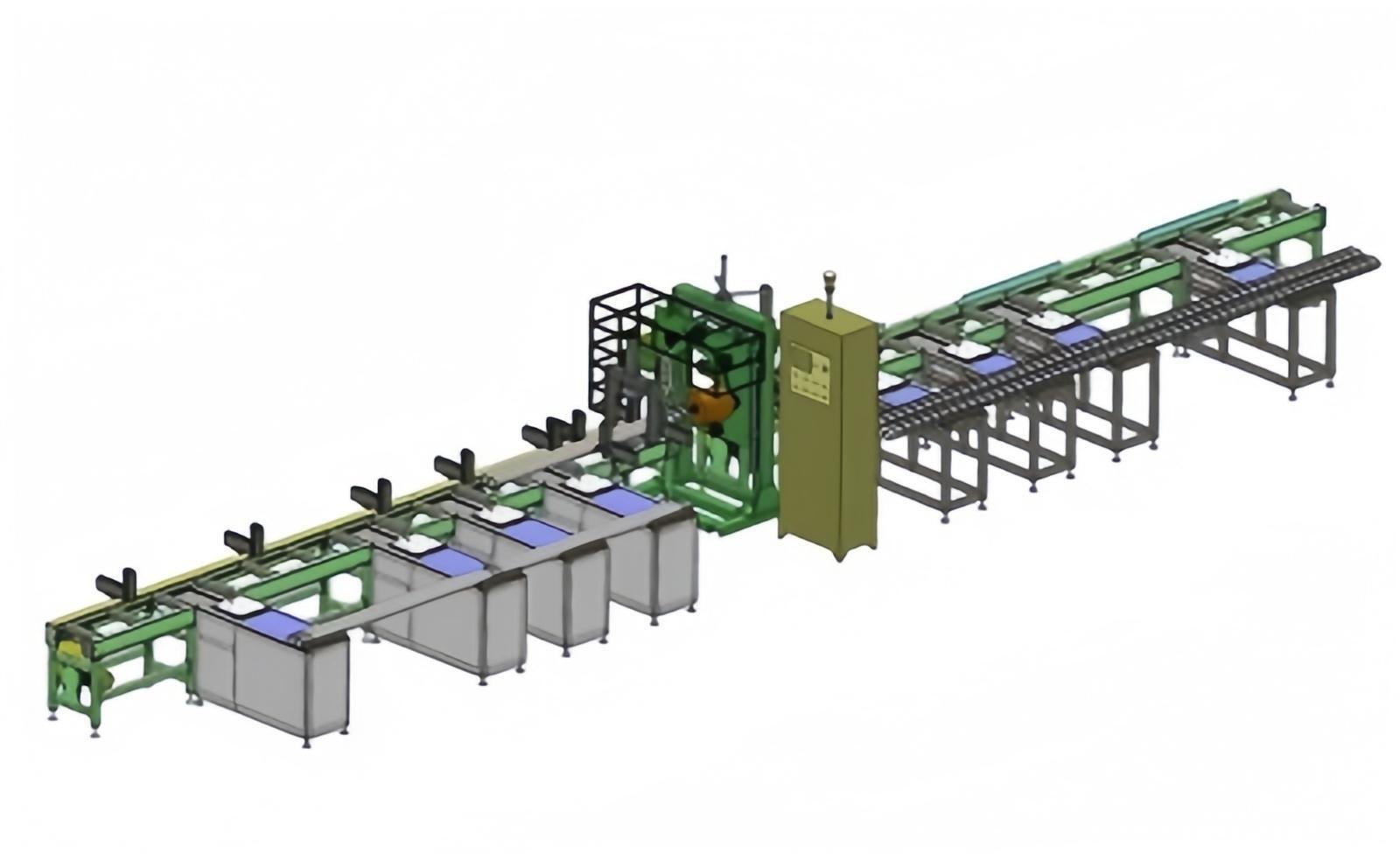

The Aluminum Profile Horizontal Stretch Wrapper Machine is a specialized packaging solution for aluminum profiles, bars, copper tubes, rods, and other related products. Designed with a focus on efficiency, energy savings, and resource optimization, this machine has gained significant market recognition. Its ability to streamline packaging processes while minimizing manpower and material usage makes it an ideal choice for various industries.

Available in multiple configurations, such as aluminum profile bundling machines, timber feeding machines, and three-sided covering machines, this solution ranges from semi-automatic setups to fully automated packaging lines to meet diverse operational needs.

Applications

The Aluminum Profile Wrapping Machine is designed for the packaging of:

Aluminum Profiles

Aluminum Pipes

Aluminum Sections

Aluminum Rods

Aluminum Bars

Key Features

1. Advanced Control System

Equipped with PLC and HMI interfaces, allowing precise operation for different product sizes and packaging requirements.

Offers both auto and manual modes with easy switching capabilities.

2. High Productivity and Cost Efficiency

Ensures faster packaging times with reduced labor and material costs, providing exceptional productivity.

3. Customizable Wrapping Performance

Features inverters for adjusting wrapping and conveying speeds.

Overlap rate is adjustable to balance material savings and secure sealing.

4. Seamless Integration

Can operate independently or in coordination with other automated equipment, forming a complete production and packaging line.

5. Automatic Film Handling

Automatically cuts and feeds packaging materials, optimizing workflow efficiency.

The system includes error detection to immediately stop operations and alert operators in case of material tearing or malfunction.

6. Protection and Stability

Tight wrapping prevents profile shifting and reduces product damage during transport.

The machine securely locks aluminum profiles together, maintaining package integrity.

7. High-Speed Ring Rotation

The wrapping ring rotates at speeds up to 100 RPM, ensuring rapid and even film application.

A specialized clutch system maintains constant tension, ensuring precise wrapping until the material roll is finished.

8. Start-Stop Mode with Automatic Cutting

At the end of each cycle, the blade automatically cuts the packing material.

The binding time can be customized to meet specific requirements.

9. Conveyor Belt System

Includes a robust belt conveyor with supportive holders to transport and position packages efficiently.

Allows for continuous packaging of different sizes without stopping, enhancing productivity.

Special Design Features

1. Sub-Bundle Strapping Machine

Equipped with a transfer belt, enabling smooth handling and bundling of smaller aluminum sections.

2. Durable Steel Frame Construction

The machine is built with a tight, sturdy steel frame for durability and long-term use.

3. Quick Material Replacement

Packing materials can be replaced in less than a minute, ensuring minimal downtime during operations.

4. Automatic Feeding and Holding

Profiles are automatically fed and held in place by a series of rollers, accommodating various package sizes seamlessly.

5. Intelligent Detection and Alarming

If wrapping material tears or malfunctions, the system halts immediately and alerts the operator, ensuring safety and operational efficiency.

Benefits

Improved Productivity: Significantly reduces packaging time while maintaining high-quality results.

Cost-Effective Operations: Saves manpower and material costs through automation and efficient film usage.

Customizable Solutions: Flexible settings and integration options cater to diverse packaging needs.

Enhanced Package Protection: Prevents movement or damage during transportation, ensuring a professional finish.

User-Friendly Design: Simplifies material replacement and operation, reducing operator effort and downtime.

Applications in Industry

The Aluminum Profile Wrapping Machine is widely used in industries such as:

Aluminum Manufacturing

Construction Materials Distribution

Logistics and Exporting

| Parameter | Specification |

|---|---|

| Voltage | AC 380/50 (or your requirement) |

| Power (KW) | 4.8 |

| OD (mm) | 300-1500 |

| Length (mm) | 2000-8000 |

| Weight (Kg) | 100-2500 |

| Packing Material | PE/Stretch film/Knit belt/VCI paper |

| Ring Speed (r/min) | 30-60 |

| Wrapping Speed | 2-16 m/min |

| Overlapping Rate | 10-90% |

Contact us to learn more and customize your machine!

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635